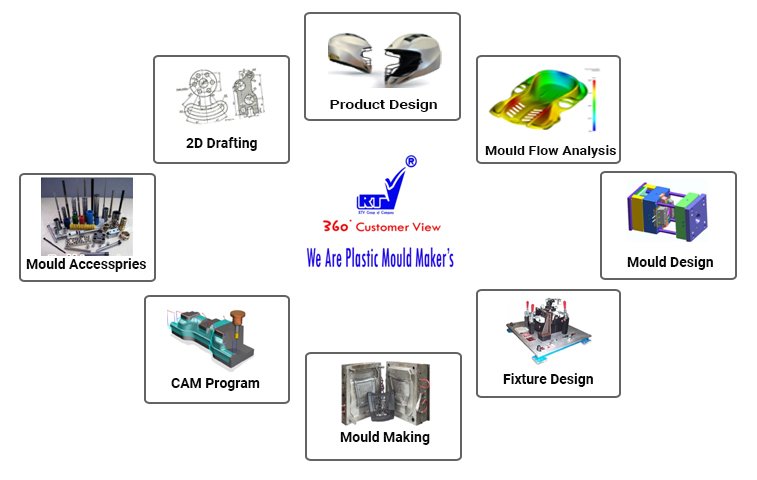

Product Design

- 3D Scanning to Product Design.

- STL File to Product Design.

- 2D to 3D Product Design.

- Video Measuring System.

- Image to. (DXF,DWG) Convert (Tol +/- 0.02mm).

- 3D Scanning to 3D Product Design.

- 3D Part File to Convert 2D (DXF, DWG).

Mould Flow Analysis

- Mould Flow Analysis with Feeding System.

- DFM with Flow Analysis.

- Solution for Weldline, Flowmark, Sinkmark, Warpage, Etc…

Mould Design

- Product Analysis.

- Draft angle Analysis.

- Ejection cum Gate Location Selection.

- Parting Line Selection with Core & Cavity Sub insert Position.

- 2Plate Mould Design with (SMPE &DME) Standard.

- 3Plate Mould Design with (SMPE& DME) Standard.

- 2K Mould Design with (SMPE & DME) Standard.

- Hot Runner System Mould Design with (SMPE & DME) Standard.

- 2D Drafting with Advance Process Layout Setting Sheet.

- Electrode Design with 3R Systems &EROVA Systems.

Fixture Design

- Product PRINTING Fixture.

- Product WARPAGE Fixture.

- Product ASSEMBLY Fixture.

- Product ULTROSONIC WELDING Fixture.

- Product PAINTING Fixture.

Mould Making

- Core, Cavity, Ejector Guide Pillar & Bush (DME, Daido, Misumi Standard).

- Sprue Bush (DME, Daido, Misumi Standard).

- Ejector Pins (DME, Daido, Misumi Standard).

- Other Mould Accessories (DME, Daido, Misumi Standard).

- Mould Base (DME Standard).

CAM Program

- Core & Cavity Machining.

- Mould Base Machining.

- 3D Profile Engraving (Use V-Tool).

- Proto Type Machining.

- Aerospace Machining.

- Production Development.